Artificial intelligence is steadily becoming a quiet but essential force in medical and pharmaceutical manufacturing. Its contributions are not always visible on the surface, yet they play a major role in improving consistency, accuracy, and regulatory alignment. In a field where even small deviations can affect product safety, AI is transitioning from a promising technology to a trusted part of routine operations.

Manufacturing environments face ongoing variability. Raw materials respond differently across batches, environmental conditions fluctuate, and manual steps naturally introduce differences. AI helps bring structure to this complexity. Rather than replacing skilled professionals, it enhances their decision-making by interpreting real-time data, identifying subtle patterns, and supporting the adjustments needed to maintain stable production.

Learning Systems Built to Strengthen Over Time

One of AI’s greatest advantages is its ability to learn continuously. Traditional automated systems operate on fixed rules, while machine learning models improve with every dataset they encounter. Over time, this allows AI to anticipate problems earlier and provide more accurate guidance.

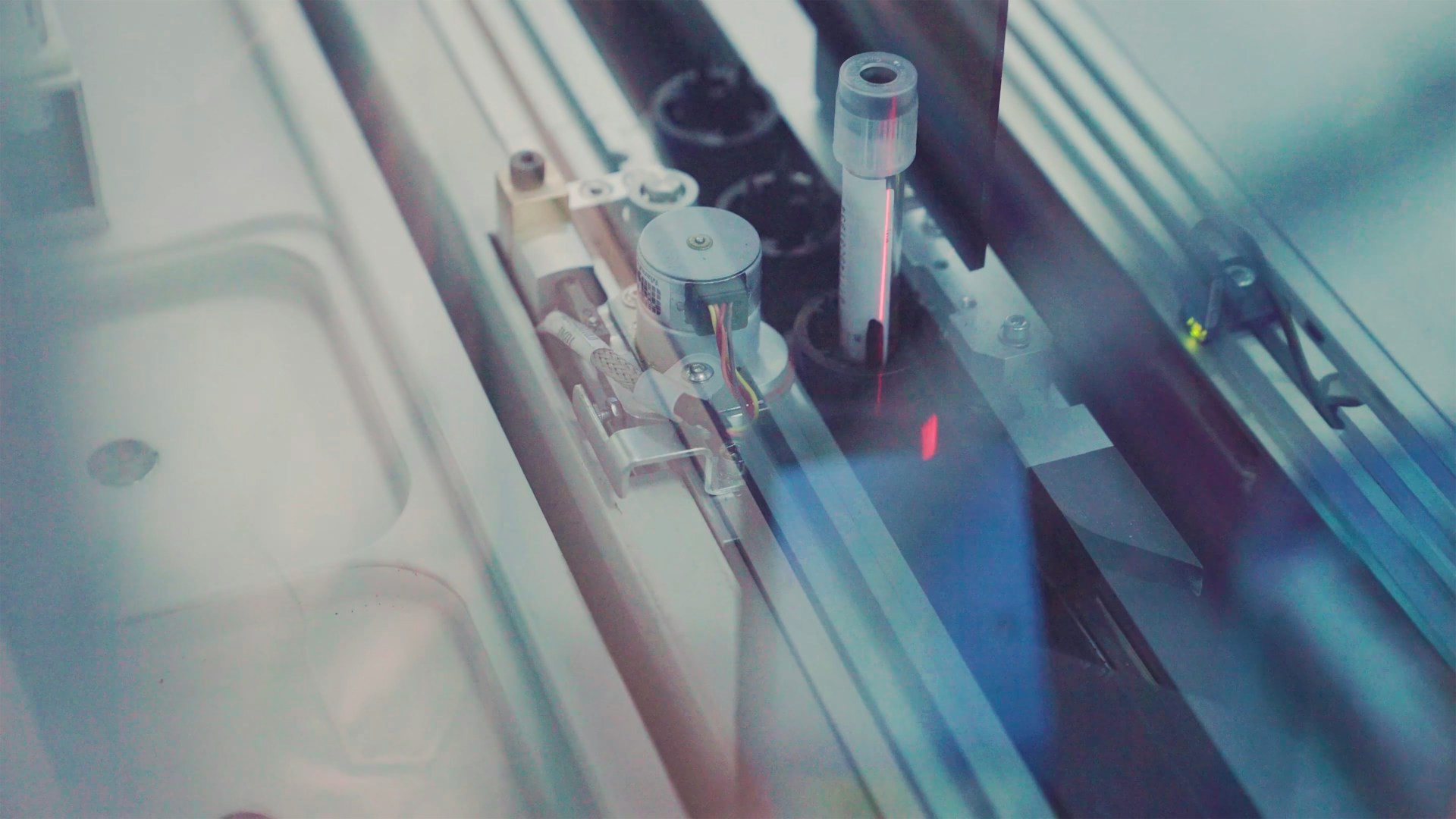

This capability is especially valuable in equipment maintenance and process optimization. AI can detect early signals of wear, strain, or performance drift long before a breakdown occurs. Small temperature changes, vibration shifts, or output fluctuations often go unnoticed during manual checks, yet AI highlights them immediately. Addressing these issues early helps limit downtime, protect batch quality, and reduce costly waste.

AI can also stabilize supply chains by analyzing multiple factors at once, including market trends, ordering cycles, and inventory levels. This helps organizations anticipate disruptions and plan accordingly.

Supporting Compliance While Advancing Innovation

Regulation plays a central role in pharmaceutical manufacturing, and any new technology must support consistent, documented compliance. AI helps simplify this process by improving clarity, accuracy, and traceability.

Natural language processing tools can interpret lengthy regulatory guidelines and distill them into usable insights for teams. Automated traceability systems document each stage of production, making audits smoother and reinforcing internal quality practices. AI does not slow down progress; instead, it helps organizations work more efficiently while ensuring all standards are met.

As AI continues to evolve, its presence in medical manufacturing will only grow. Its purpose is not to replace people, but to support a smarter, more adaptable production environment where reliability, efficiency, and precision continue to improve.

For additional insight into how AI is redefining standards in pharmaceutical production, explore the visual guide accompanying this article from Advanced Technology Services, a provider of machine health monitoring systems.